HARDWOOD GRADES AND MEASUREMENT

In 1898 the National Hardwood Lumber Association was established, with the express purpose of establishing a uniform system of grading rules for the measurement and inspection of hardwood lumber. The National Hardwood Lumber Association developed the uniform system of grading with the cooperation of both producers and consumers of hardwood lumber. This system of grading hardwood lumber has been revised and enlarged to reflect the evolution of the hardwood lumber industry. Since the original adoption of this grading system, no major changes in the standards have occurred that were not prompted by a change in the quality or availability of the timber supply.

Hardwood lumber is lumber that is produced from deciduous trees (a tree which drops it leaves each year). Softwood lumber is produced from coniferous trees (evergreens). Hardwood lumber is graded on its usable content aside from the parts of the board that may be considered undesirable, such as knots, wane, and splits. Softwood lumber is graded for appearance by the whole piece.

Each grade of hardwood lumber is determined by the size and number of clear wood cuttings which a board will yield when cut up and used in the manufacture of a hardwood product. Hardwood lumber is normally graded from the poorer quality face with a few exceptions, such as 1F, Selects, and surfaced lumber. The higher the grade of the lumber, the greater the size of clear wood cuttings and the fewer the number of cuttings allowed. The lower the grade of lumber, the smaller the size of clear cuttings and the greater the number of cuttings allowed.

Hardwood lumber is measured and sold by the board foot. One board foot of lumber would be a piece 1" thick by 12" wide by 12" long. The formula for determining board footage is (thickness in inches x width in inches x length in feet / 12). All lumber thicknesses of 1" and below are measured as 1". When determining the length of a board on domestic hardwoods the length is measured in whole feet. For example a board measuring 8’6" would be considered 8’ long, a board measuring 8’11" would be considered 8’ long also. For imported hardwoods the length is determined to the nearest whole foot. For example a board measuring 8’5" would be considered 8’ long, a board measuring 8’7" would be considered 9’ long.

A good practice when receiving lumber in, is to do a quick estimate on the lumber to be sure you are receiving all the lumber you are being invoiced for. At Schaller Hardwood Lumber Company we have found the following method to be the most accurate. Measure the width of each piece in an average layer in the bundle, adding the widths together as you go. Multiply the total width of the pieces by the average length of the bundle and multiply by the thickness of the lumber, then divide by 12. This will give you the average board footage per layer of lumber. Multiply this average by the number of layers, this should give you a good estimate of the board footage in the bundle. NOTE: When measuring the width of a bundle, each piece in the layer should be measured individually, do not take just the total width of the bundle. If you take the total width of the bundle you do not allow for the space between each board, thus giving you a less then accurate estimate.

Forest Fact: National forests are America’s Great Outdoors. They encompass 191 million acres (77.3 million hectares) of land, which is an area equivalent to the size of Texas.

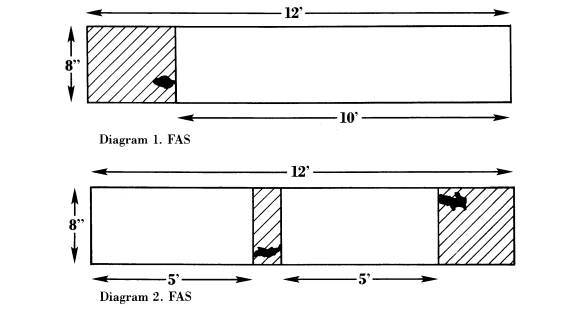

EXPLANATION OF HARDWOOD GRADES

FAS (First and Seconds)—The FAS grade will provide the hardwood lumber user a board containing long, wide, clear cuttings. This grade is most often used by, moulding manufacturers, in architectural millwork, and custom cabinet shops. The FAS grade lumber will include lumber that will yield from 83-1/3% to 100% clear wood in minimum sized cuttings at least 3" wide by 7’ long or 4" wide by 5’ long. The width and the length of the board determine how many cuts may be used to obtain the percentage of clear cut lumber. The longer and wider the board the greater the number of cuts that may be used to obtain the percentage of clear cut lumber. The minimum size kiln dried board in the FAS grade is 5-1/2" wide by 8’ long. Note: a common misconception is that a FAS board must be 6" or wider, however this width requirement applies to green lumber, the requirement for kiln dried lumber is the 5-1/2" width which allows for the shrinkage that occurs during kiln drying. The following diagram shows examples of two boards with the cuts needed to make a FAS grade. The clear unshaded areas are the examples of clear cuts. The shaded areas contain the defects and are not used in the clear cuttings, although there may well be good useable material in the shaded areas it does not meet the minimum size cut for the FAS grade.

1F (1 Face)—The 1F grade is almost always grouped together with the FAS grade. The 1F grade is obtained by grading both faces of the board. The best face must meet the requirements of an FAS grade, while the poorer face must meet the grade requirements of an #1 Common grade.

SELECTS—The select grade is essentially the same grade lumber as the 1F grade, except for the minimum board size. Select grade lumber’s minimum board size after kiln-drying is 3-1/2" wide by 6’ long.

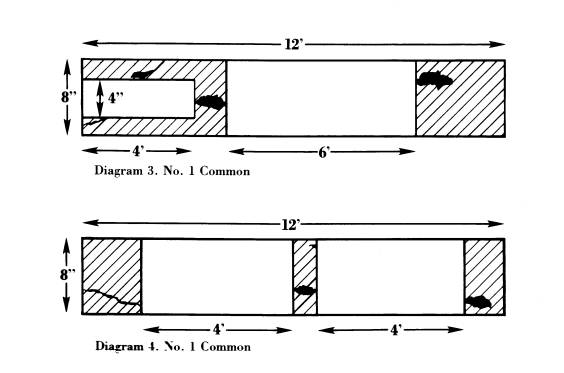

#1 COMMON—The #1 Common grade will provide the hardwood lumber user with medium sized clear cutting. This grade is, most often used by cabinet manufacturers, cabinet door manufacturers, and furniture manufacturers. The #1 Common grade will include boards that will yield 66-2/3% to 83-1/3% in minimum size clear wood cuttings of at least 3" wide by 3’ long or 4" wide by 2’ long. The greater the width and length of the board the greater the number of clear wood cutting allowed to achieve the yield percentage. The minimum size board allowed in the #1 Common grade is after kiln-drying 2-1/2" wide by 4’ long. Note: the minimum size for green lumber is 3" wide by 4’ long. The following diagrams show examples of two #1 Common boards. The clear unshaded areas are examples of how the board would be cut to make the #1 Common grade. The shaded areas are examples of areas that contain defects that cannot be used in clear cuts. The shaded areas may well contain good clear useable material, however it does not meet the minimum size requirement of cut size for a #1 Common grade.

A couple observations on lumber grades that were made by the employees of Schaller Hardwood Lumber Company that may benefit the hardwood lumber consumer.

1) Companies that sell their Red Oak lumber as a Select & Btr grade as compared to a FAS&1F grade will have a overall lower quality grade of #1 Common lumber because the Select boards are in the Select & Btr lumber rather then in the #1 Common lumber.

2) Short lengths (4’-6’) in #1 Common lumber will often yield as high a percentage of clear lumber as longer lengths in FAS&1F. These short lengths become a particularly good buy for that customer that does not need the longer length.

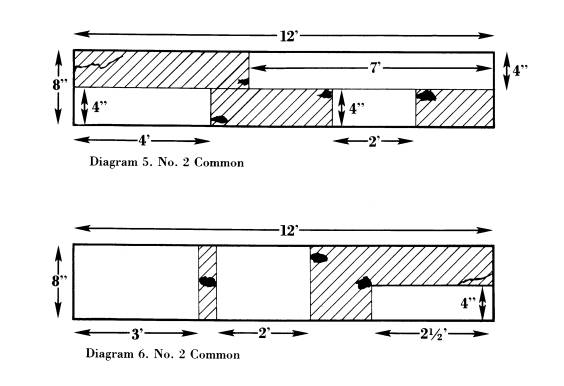

#2 COMMON—The #2 Common grade will provide the hardwood lumber user with short and narrow clear cuttings. This grade is, most often used by large-scale box cabinet producers, some cabinet door manufacturers, flooring, picture frames, and unexposed hardwood framing. The #2 Common grade will include boards that will yield 50% to 66-2/3% in minimum size clear wood cuttings of at least 3" wide by 2’ long. Again the greater the width and length of the board the greater the number of clear wood cuttings allowed to achieve the yield percentage. The minimum size board allowed in the #2 Common grade after kiln drying is 2-1/2" wide by 4’ long. Note: the minimum size for green lumber is 3" wide by 4’ long. The following diagrams show examples of two boards that grade #2 Common. The clear unshaded areas are the clear cuts used to determine the grade. The shaded areas represent material that cannot be used in determining grade because of defects, although there may be useable material in these areas it can not be used because it does not meet the minimum cut size for the #2 Common grade.

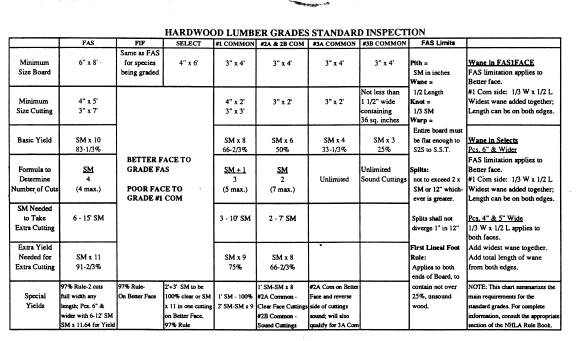

The following table gives a good summarized comparison of the standard hardwood lumber grades. The grading standards for some of the species of hardwood lumber differ from the standardized grades, such as Walnut and Butternut. For specific grading standards of the different species of lumber consult the National Hardwood Lumber Association "Rules For The Measurement and Inspection of Hardwood and Cypress" or one of Schaller Hardwood Lumber Company’s National Hardwood Lumber Association trained hardwood lumber inspectors, Scott Lundstrom, Willie Goin, Dave Holmes, Roger Lockwood, Kirk Weatherford and Herschel Vernon. All of the above individuals have completed and graduated from the National Hardwood Lumber Association’s Inspection School. The National Hardwood Lumber Association’s Inspection School provides a 14 week course with the emphasis on the practical application of the rules. The students receive both classroom training and hands on experience in the school’s lumber handling facilities.

Schaller Hardwood Lumber Company is a participant in the National Hardwood Lumber Association’s Certification Program. This program is a voluntary quality assurance program. A National Inspector will perform random grade sampling at a member’s location. If the company’s random sample is within 4% of the value determined by the National Inspector the company is granted certification. This certification is kept current by follow up checks at least twice a year to maintain tight compliance with the National Hardwood Lumber Association grading rules. This certification provides the company with a independent quality control check.

REMEMBER the above information is just a short generalization of the grading rules established by the National Hardwood Lumber Association. The actual grading and measurement of hardwood lumber is not a simple process. It takes months of study and years of experience to become proficient in the application of the grading rules. If you desire more information or knowledge the National Hardwood Lumber Association provides two and three day lumber grading short courses through out North America. These short courses will help broaden the student’s general knowledge of the grading rules.